Dali nga mga Detalye

Kahimtang: Bag-o

Boltahe: AC380V / 220V

Dimensyon(L*W*H): 1500*3040mm

Timbang: 980KGS

Sertipikasyon: CE

Warranty: usa ka tuig

Gihatag nga Human nga Pagbaligya nga Serbisyo: Ang mga inhenyero magamit sa makinarya sa serbisyo sa gawas sa nasud

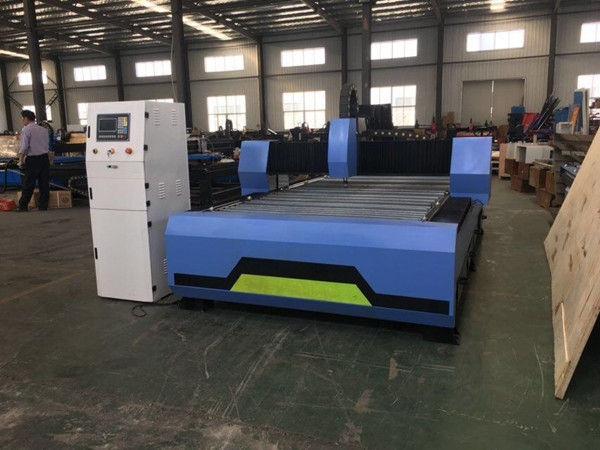

Produkto: Daghang stainless steel plate cutting machine OP1530

Lugar sa pagtrabaho: 1500 * 3000mm

Gidak-on sa lamesa: 1700 * 3540mm

3 Axis Control Motor: stepper motor

Pagbalikbalik: +/- 0.02mm

Pagputol sa gikusgon: 8m/min

Gahum sa plasma: 60A, 100A, 120A, 200Aetc

Pagtrabaho nga boltahe: 380v / 220v, 3 nga hugpong sa mga pulong

Gibag-on sa pagputol: 0.3-40mm

Pinulongan sa sugo: G code

CNC Plasma Cutting Machine Mga Parameter

| X, Y-Axis nga Pagbiyahe | 1300 * 2500mm |

| Dimensyon sa Lawas | 1500*3040mm |

| Gahum sa Plasma | 60A, 100A, 120A, 200A etc USA Hypertherm |

| Istruktura sa Talaan | plasma espesyal nga refractory steel lamesa +6mm blade |

| Pag-usab | +/- 0.02mm |

| katulin sa pagtrabaho | 8m/min |

| Max. Kusog nga Bilis sa Pagbiyahe | 30m/min |

| Pagputol nga gibag-on | 0.3-40mm |

| Traverse nga sistema | Linear nga giya sa 3 axis |

| Controller | Pagsugod sa controller (uban sa THC height controller) |

| nagtrabaho nga boltahe | 380V/220V, 3 nga hugpong sa mga pulong |

| command language | G Code |

CNC Plasma Cutting Machine Mga Tampok

1 Gisulayan nga lubid nga higdaanan sa gibug-aton nga gibug-aton nga profile nga puthaw, labi nga lig-on ug lig-on.

2 Makatarunganon nga laraw sa lamesa nga lathe, 10 mm nga gibag-on nga mga plate nga asero nga gipahimutang sa lamesa sa lathe nga gitabonan sa cast sheath nga adunay mga pako. Ang mga steel plate dili madaut bisan sa ilawom sa nagdilaab nga siga. Ang kalainan sa lebel sa tibuuk nga platform sa double-deck nagpabilin sa 0-1.5mm.

3 Taas nga kalidad nga stepper motor ug taas nga katukma nga rack transmission. Ubos nga kasaba, lig-on ug tukma nga paglihok sa koordinasyon.

5 DSP offline nga kamot controller; Software Type3 ug Ucancam nga adunay auto material saving function.

6 Standard configuration: Fuli 100A plasma generator, nga makaputol sa 10mm metal plate.

7 Labing maayo nga kapilian alang sa tanan nga mga matang sa lainlaing gibag-on nga materyal ug heterotypic sheet cutting.

Pagkontrol sa taas nga kapasidad

Ang advanced nga taas nga linear calibration nga teknolohiya naghimo sa cutting nozzle ug cutting board nga sulod sa 3 ~ 30mm sa automatic nga pagkontrol sa gitas-on sa capacitance mode;

Yano ug sayon nga linearization calibration

Ang gimbuhaton sa "Usa ka yawe alang sa pag-calibrate sa gitas-on" naggarantiya nga sa bisan unsang mga kahimtang, ang tiggamit kinahanglan ra nga mopilit sa usa ka yawe, mahimo niyang i-calibrate ang hingpit nga pagsukod sa gitas-on ug makab-ot ang usa ka linear nga pagsukod sa gitas-on.

Ang sistema sa pagkontrol sa OMNI THC makahimo sa

1. Buhata ang pagkontrol sa tulin sa suok ug pagkontrol sa gitas-on,

2. Pagpasig-uli sa breakpoint, awtomatik nga pagbawi sa kusog ug awtomatik nga memorya sa breakpoint,

3. Espesyal nga short line machining feature base sa hapsay nga pagbiyahe, kaylap nga magamit sa metal blanking ingon man sa advertisement

4.Advanced nga materyal nga hilig sa pagdiskarga nga disenyo. Ang tanan nga nahuman nga mga piraso sa trabaho ug mga tipik nag-slide sa tunel alang sa luwas ug sayon nga pagkolekta.